High Input Voltage Monolithic Switcher Steps Up and Down Using Single Inductor

High Input Voltage Monolithic Switcher Steps Up and Down Using Single Inductor

著者

Jay Celani

2003年12月01日

Introduction

Ultra-wide input voltage requirements are a common design problem for DC/DC converter applications. When that range includes voltages both above and below the output voltage, a converter must perform both step-up and step-down functions, making the design problem even more complex. A high-voltage input range makes the problem even tougher. These design issues are commonplace in the automotive environment, where battery powered electronics have to handle everything from cold crank to load dump, a range that can span from 4V to 60V. The requirements of an automotive battery-powered design are somewhat unique, as the operational input voltage is typically relatively well controlled, but an ultra-wide input range must be considered since short-duration events can create extreme input voltage shifts.

There are several common solutions to the step-up/step-down problem. One solution is to cascade multiple circuits, such as a boost converter followed by a buck converter or an LDO, where the boost converter prevents the output of the step-down converter from dropping out at low input voltages. With high input voltages, the upper bound of the input voltage is directly imposed on the step-down stage, which makes use of an LDO impractical. Cascading a boost converter and high-voltage buck converter will work, but such a topology incurs penalties of complexity, reduced efficiency, and cost. A SEPIC converter is a popular topology for step-up/step-down applications, but a SEPIC converter has inherent drawbacks such as the expense of two inductors, low efficiencies, high switch voltage and current stresses, and high output ripple currents.

Enter the LT3433, a high-voltage monolithic DC/DC converter that incorporates two switch elements, allowing for a unique topology that accommodates both step-down and step-up conversion using a single inductor. When the input voltage is significantly higher then the output, the LT3433 operates in a modified non-synchronous buck configuration using a boosted-drive high-side switch. When the input voltage approaches or falls below the output voltage, the LT3433 activates a ground-referred switch, which creates a bridged switching configuration, or a buck/boost converter, allowing for very low dropout and/or step-up conversion. The LT3433 is primarily intended for use in step-down applications that have transient low voltage input requirements, such as 12V automotive applications that must support a cold-crank condition, where the battery-rail can briefly drop down to 4V. The LT3433 could also be used to significant benefit in certain applications where a SEPIC topology is currently the best option.

What’s Inside?

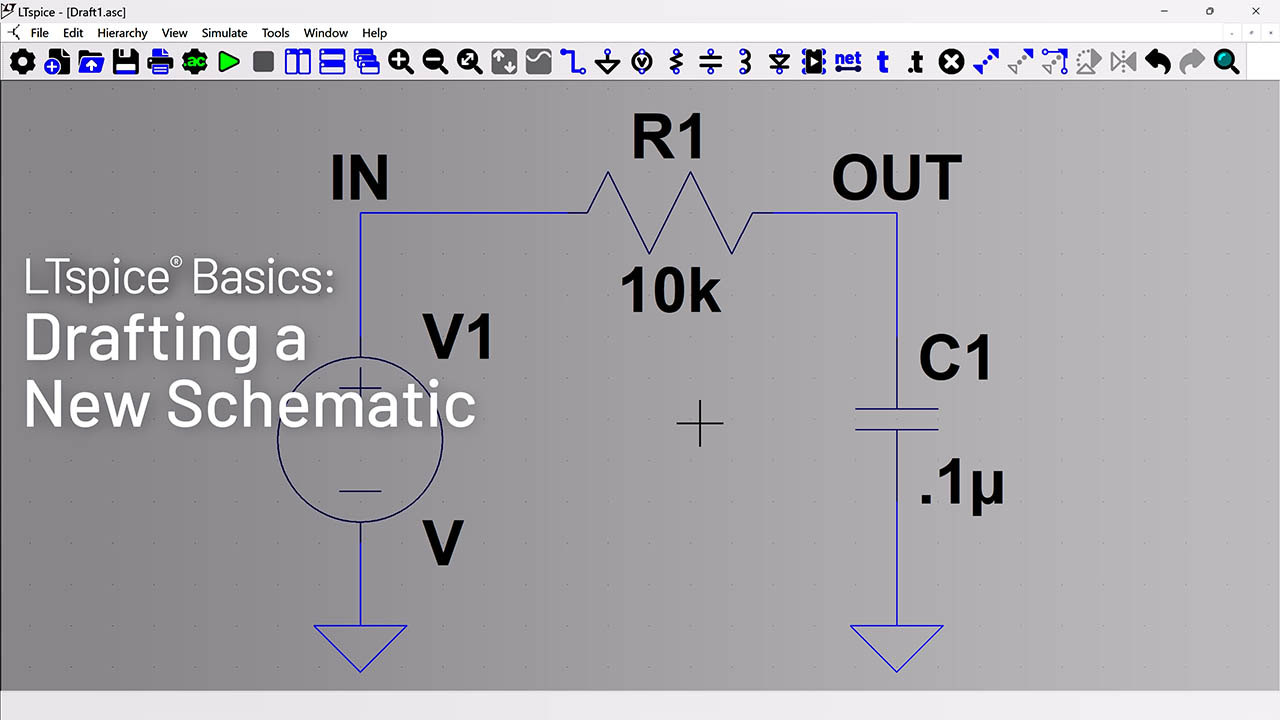

The LT3433 incorporates a 200kHz constant frequency, current mode architecture and can operate with input voltages from 4V to 60V. The LT3433 is packaged in a 16-pin fused TSSOP exposed pad leadframe package, which provides a small footprint and excellent thermal characteristics. An internal 1% voltage reference allows programming of precision output voltages up to 20V using an external resistor divider. A block diagram of the LT3433 is shown in Figure 1.

Figure 1. LT3433 block diagram.

Burst Mode operation improves efficiencies during light-load conditions. The LT3433 quiescent current drops to ~100μA while in Burst Mode operation, minimizing maintenance power for battery powered applications. Burst Mode operation can be disabled by shorting the BURST_EN pin to either the VOUT pin or the VBIAS pin, or by biasing the pin using an external supply. Shorting BURST_EN to ground enables Burst Mode. The LT3433 also has a low-current shutdown mode, reducing quiescent current to ~10μA when the SHDN pin is pulled below 0.4V.

The LT3433 uses both current limit and frequency foldback to help control inductor current runaway during startup and short-circuit conditions. A soft-start feature is also included to reduce output overshoot and inrush currents during startup. Soft-start duration is controlled by a capacitor placed between the SS pin and ground. The LT3433 does not suffer from current limit reduction typically associated with slope-compensation, so switch current limit is unaffected by duty-cycle.

Switching between buck and buck/boost modes of operation is controlled automatically by the LT3433. While in buck mode, if the converter input voltage becomes close enough to the output voltage to require a duty-cycle greater than 75%, the LT3433 enables a second switch during the “switch on” time, which pulls the output side of the inductor to ground. This bridged-configuration switching operation allows voltage conversion to continue when VIN approaches or is less than VOUT.

Bridged Topology

In the simplest terms, a buck DC/DC converter switches the VIN side of the inductor, while a boost converter switches the VOUT side of the inductor. The LT3433 bridged topology merges the elements of buck and boost topologies, providing switches on both sides of the inductor, as shown in Figure 2. Operating both switches simultaneously achieves both step-up and step-down functionality.

Figure 2. Merging the elements of a buck DC/DC converter topology and a boost DC/DC converter topology form the LT3433 bridged network, enabling buck/boost conversion using a single inductor.

Maximum duty-cycle capability (DCMAX) gates the dropout capabilities of a buck converter. As VIN – VOUT is reduced, the required duty cycle increases toward DCMAX until the limit of the converter is reached, and the converter loses regulation. With a second switch bridging the switched inductor between VIN and ground, the entire input voltage is imposed across the inductor, which reduces the duty cycle required to maintain regulation. Using this topology, regulation is maintained as VIN approaches or drops below VOUT.

4V–60V Input to 5V Output Automotive Converter

A 4V–60V to 5V converter is shown in Figure 3. This design is well suited to 12V automotive applications where output regulation is required with battery line voltages from 4V cold crank through 60V load dump. The input voltage threshold for bridged mode operation is near 8V, so the converter operates primarily in buck mode, except during a cold crank condition. This converter accommodates loads up to 400mA and produces efficiencies greater than 83% when operating with a nominal 13.8V input. Conversion efficiencies with VIN = 4V and VIN = 13.8V in both burst-enabled and burst-disabled configurations are shown in Figure 4.

Figure 3. 4V–60V to 5V converter.

Figure 4. Conversion efficiency of the 4V–60V to 5V converter shown in Figure 3.

During a cold-crank condition, where the battery line voltage drops below 8V, the converter switches into buck/boost mode to maintain output voltage regulation. Because the LT3433 switch current limit is fixed, converter load capability is reduced while operating as a buck/boost converter. Output current capability vs. input voltage is shown in Figure 5. With an input of 4V, the converter accommodates loads up to 125mA.

Figure 5. Maximum output current vs VIN for the 4V–60V to 5V converter shown in Figure 3.

It is important to use low-VF Schottky diodes in a LT3433 converter design. Minimizing the forward voltages of the external catch and forward diodes directly reduces operational duty cycle, which increases output current capability, especially during bridged switching. Reduced Schottky forward voltages also increase operational efficiency, which further increases available output current capability. The B120/160 diodes used are a good compromise between size and low VF. An inductor with low series resistance also helps to maximize converter efficiency and performance.

In maintenance applications, reduced Q-current operation is desired for light-load and no-load conditions. This is easily accomplished by shorting the BURST_EN pin to SGND to enable Burst Mode. In certain low-current applications, however, the IC could enter burst operation during normal load conditions. If the additional output ripple and noise generated by Burst Mode operation is not desired for normal operation, BURST_EN can be biased using an external supply that is disabled during a no-load condition. This prevents entering Burst Mode operation during normal operation, and enables Burst Mode operation only when it is required. The 4V–60V to 5V automotive converter shown in Figure 6 incorporates a dynamic Burst Mode function controlled by a switched battery input, and also accommodates a user-enabled shutdown feature.

Figure 6. 4V–60V to 5V converter with switched Burst Mode enable and shutdown.

Not only does this LT3433 converter operate across a large range of DC input voltages, it also maintains tight output regulation during input transients. When subjected to a 1ms 13.8V to 4V input transition to simulate a cold crank condition, regulation is maintained to 1% with a 125mA load, as shown in Figure 7.

Figure 7. 4V–60V to 5V converter output characteristic (AC coupled) during a 13.8V to 4V 1ms VIN transition with 125mA output load.

Increased Output Voltages

The LT3433 can be used in converter applications with output voltages from 3.3V through 20V, but as converter output voltages increase, output current and duty cycle limitations can prevent operation with VIN at the extreme low end of the LT3433 operational range. When a converter operates as a buck/boost, the output current becomes discontinuous, which reduces output current capability by roughly a factor of (1 – DC), where DC = duty cycle. As such, the output current requirement dictates a minimum input voltage where output regulation can be maintained. Figure 8 shows typical minimum input voltages as a function of converter output voltage and required load current.

Figure 8. Typical LT3433 converter minimum input voltages vs VOUT for various maximum load currents.

8V–60V to 12V Converter

The 8V–60V to 12V converter shown in Figure 9 can provide output current up to 125mA with inputs as low as 8V. This is suitable for 12V automotive applications without cold-crank requirements, as well as many other applications such as those powered by inexpensive wall adapters. This converter typically switches operational modes at 17V and operates in buck mode with higher input voltages. This LT3433 converter accommodates loads up to 435mA and produces efficiencies above 89% when operating with a 20V input. Conversion efficiencies with VIN = 8V and VIN = 20V in both burst-enabled and burst-disabled configurations are shown in Figure 10. Output current capability vs. input voltage is shown in Figure 11.

Figure 9. 8V–60V to 12V converter.

Figure 10. Conversion efficiency of the 8V–60V to 12V converter.

Figure 11. Maximum output current vs VIN for the 8V–60V to 12V converter.

Conclusion

The LT3433 simplifies the design of ultra-wide input range DC/DC voltage converters, and is particularly suited for step-down applications that require short-duration step-up conversion. Automatic transitioning between buck and buck/boost modes of operation provides seamless output regulation over wide input voltage ranges and during input voltage transients. The outstanding thermal characteristics of the TSSOP package make the LT3433 usable in harsh environments, and the small-footprint package, use of a single inductor, and few external components provide board space efficient solutions.

著者について

この記事に関して

{{modalTitle}}

{{modalDescription}}

{{dropdownTitle}}

- {{defaultSelectedText}} {{#each projectNames}}

- {{name}} {{/each}} {{#if newProjectText}}

-

{{newProjectText}}

{{/if}}

{{newProjectTitle}}

{{projectNameErrorText}}