Noise, Vibration, and Harshness (NVH) Automotive Solutions

When developing new technologies such as motors or power steering, it is critical to understand how the device will respond to real-world variables like road vibrations and other harsh conditions. Unwanted sound or disruption in an electronic signal can create an audible disturbance that negatively impacts the consumer’s driving experience. Worse, unmitigated vibration can damage electrical and mechanical components over time, leading to potential catastrophic failure.

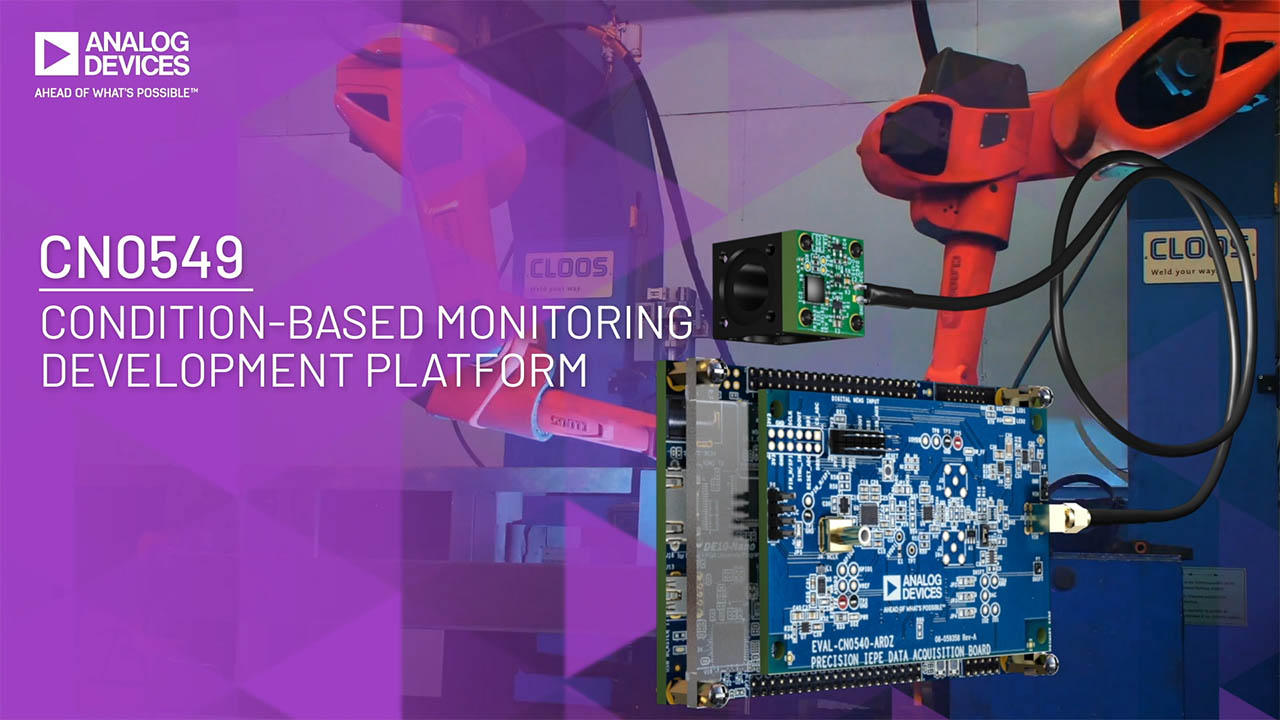

Vehicle drive testing can help address these challenges in the research and development phase so that noise reduction technologies can be implemented and validated. In contrast, condition-based monitoring (CbM) measures similar inefficiencies in motors and machinery typically for continuous monitoring after they have been deployed. NVH testing is primarily utilized during the R&D or qualification phases, whereas CbM is targeted for monitoring existing machinery in operation or for predictive maintenance.

Value and Benefits

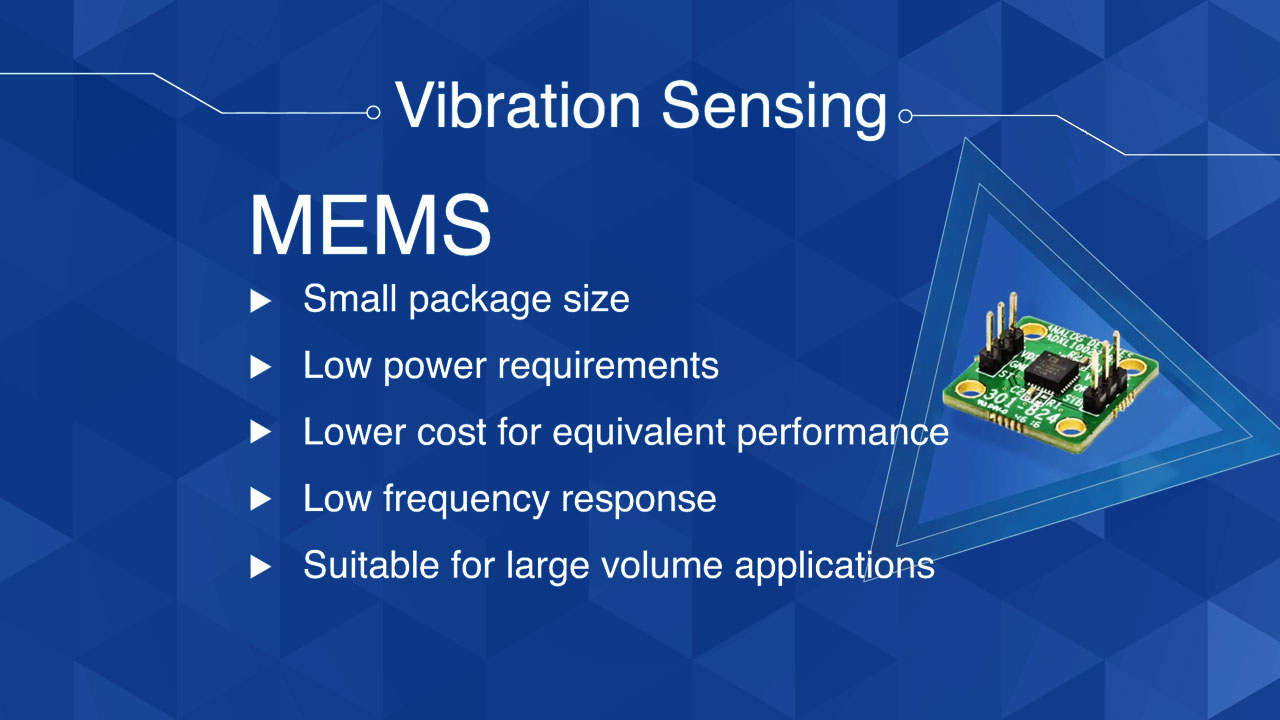

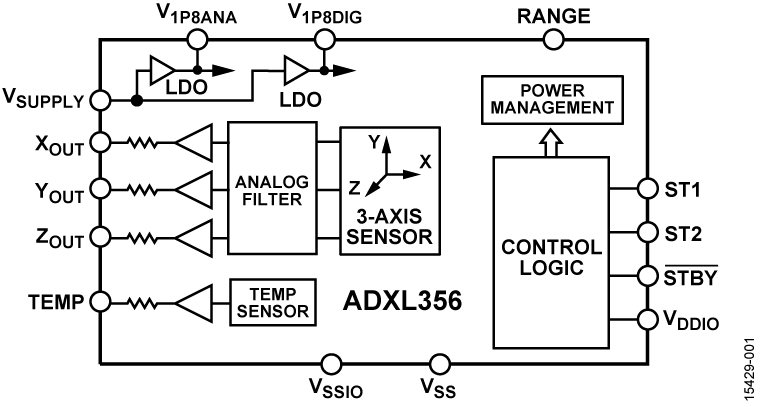

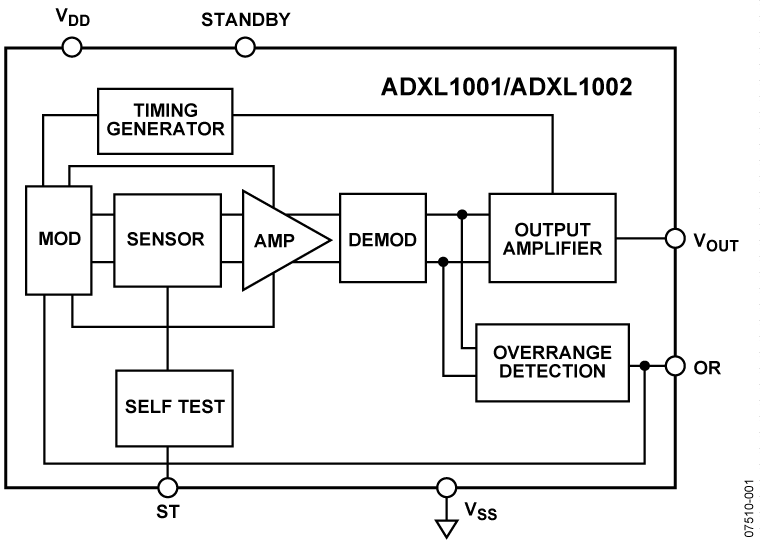

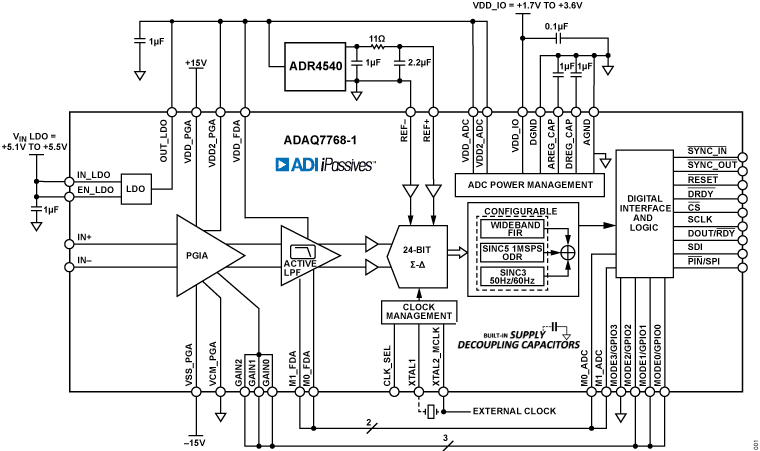

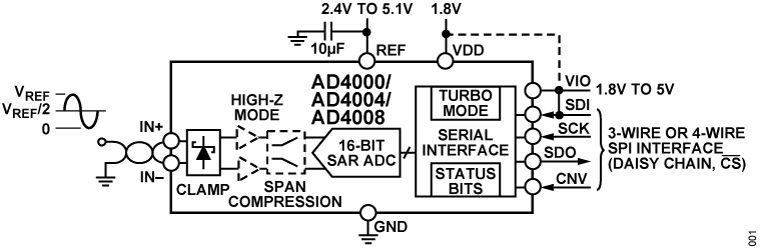

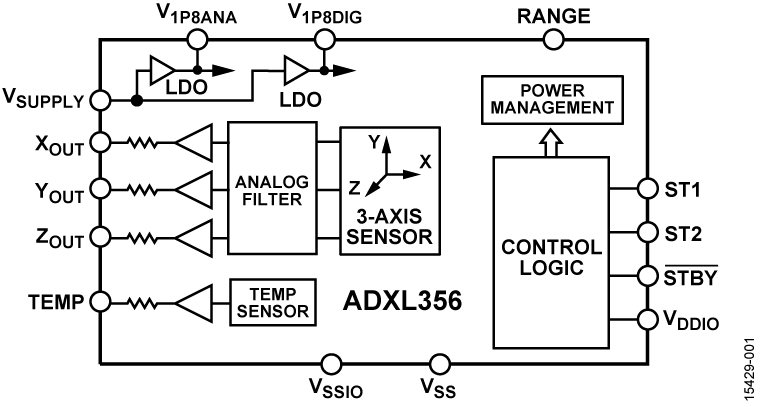

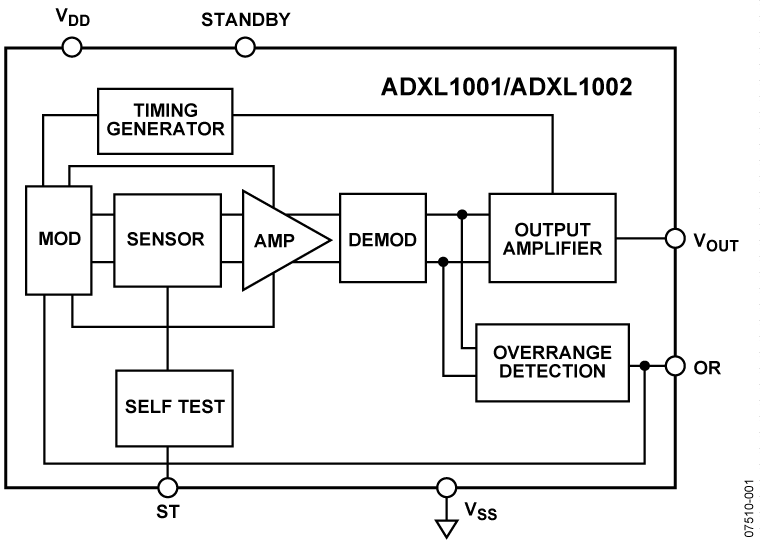

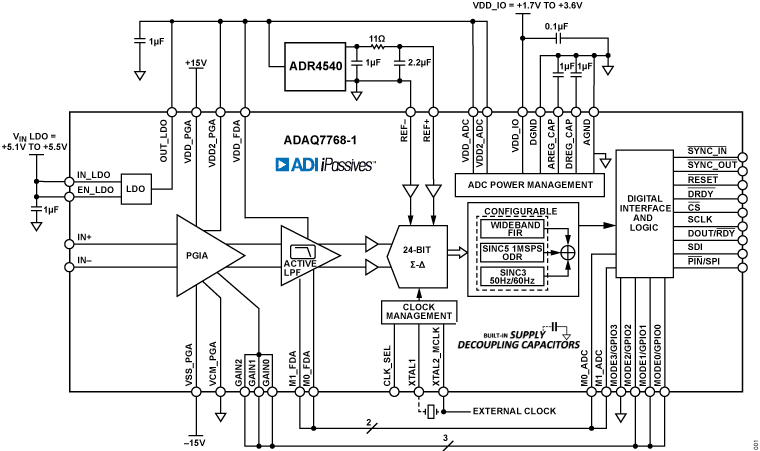

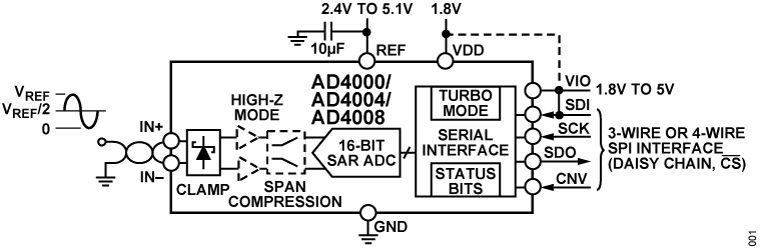

Analog Devices helps enable next-generation NVH solutions through compact high-performance inertial measurement solutions, including both MEMs-based as well as piezoelectric sensor-based solutions.

Enable high-accuracy, wide bandwidth vibration analysis

Flexible, compact, and low power for portable monitoring

Enable analytics or training data for predictive maintenance

Featured Products

Interactive Signal Chains

Evaluation Boards

Key Resources

Informational

Training and Support

Trainings and Tutorials

{{modalTitle}}

{{modalDescription}}

{{dropdownTitle}}

- {{defaultSelectedText}} {{#each projectNames}}

- {{name}} {{/each}} {{#if newProjectText}}

-

{{newProjectText}}

{{/if}}

{{newProjectTitle}}

{{projectNameErrorText}}