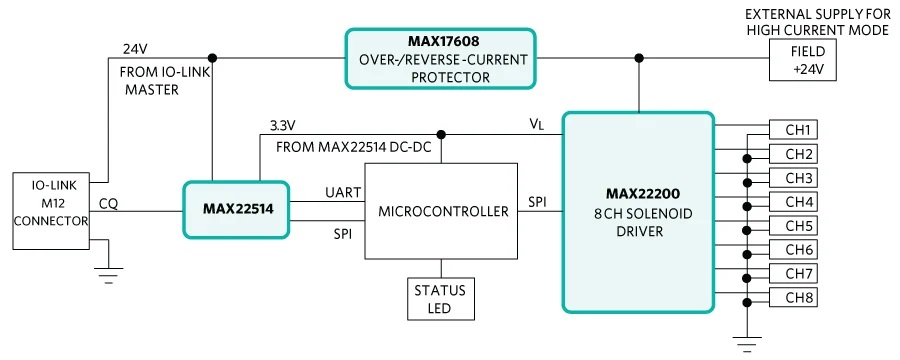

The MAXREFDES278# IO-Link octal solenoid driver consumes minimal power, and space, making it a complete solution for many actuators found in various industrial control and automation applications.

The MAX22514 IO-Link device transceiver is compliant with the IO-Link version 1.1/1.0 physical-layer specification. It integrates the high-voltage functions commonly found in industrial sensors and actuators, including drivers, and two linear regulators. The MAX22514 features extensive integrated protection to ensure robust communication in harsh industrial environments. All three I/O pins (V24, C/Q, and GND) are reverse-voltage and short-circuit protected and feature integrated ±1kV/500Ω surge protection. This enables a very small PCB area with no required external protection components, such as TVS diodes. The low on-resistance driver (C/Q) further reduces power dissipation so that this reference design consumes minimal power with very low thermal dissipation. Operation is specified for normal 24V supply voltages up to 36V. Transient protection is simplified due to high voltage tolerance (i.e., 65V absolute maximum rating for the I/O pins without the integrated TVS diodes) in addition to the integrated surge protection.

The integrated DC-DC regulator in the MAX22514 generates the 3.3V supply for the microcontroller as well as the MAX22200, reducing the number of additional external components and the required space.

The MAX22514 features high configurability as well as diagnostics through an SPI interface and a 3-wire UART interface is provided for IO-Link communication.

The MAXREFDES278# does not require external protection devices such as varistors or TVS diodes due to the integrated surge protection in the MAX22514 at the IO-Link interface. This reference design meets both IEC 61000-4-2 for electrostatic discharge (ESD) up to ±4kV and IEC 61000-4-4 for electrical fast transient (EFT) ±4kV standards. The IO-Link side is designed to meet a surge capability (2A at t = 1.2/50μs) up to ±1.0kV.

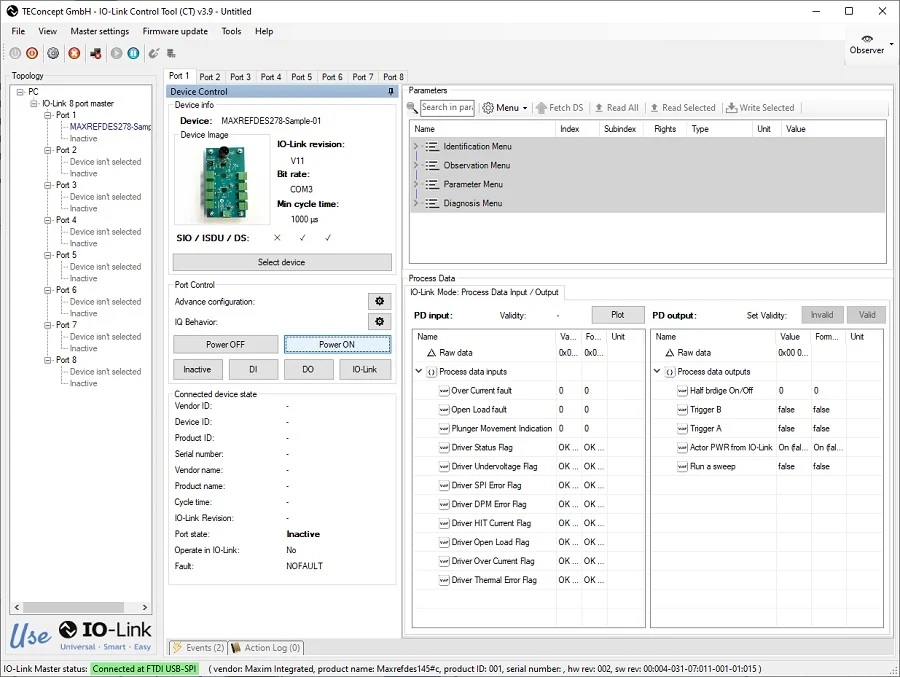

The MAX22200 is an octal 36V serial-controlled solenoid driver. Each channel features a low impedance (200mΩ typ) push-pull output stage with sink-and-source driving capability and up to 1ARMS driving current. A serial interface (SPI) that also supports daisy-chain configurations is provided to individually control each channel. The device half-bridges can be configured as low-side drivers or as high-side drivers. Moreover, pairs of half-bridges can be paralleled to double the driving current or can be configured as full-bridges to drive up to four latched valves (bi-stable valves) or four brushed DC motors. Two control methods are supported; voltage drive regulation (VDR) and current drive regulation (CDR). In VDR, the device outputs a pulse-width modulation (PWM) voltage in which the duty cycle is programmed using SPI. For a given supply voltage and solenoid resistor, the output current is proportional to the programmed duty cycle. In CDR, an internal integrated lossless current sensing (ICS) circuit senses the output current and compares it with an internal programmable reference current.

For optimal power management in solenoid drive applications, the excitation drive level (IHIT), the hold drive level (IHOLD), and the excitation drive time (tHIT) can be individually configured for each channel. The MAX22200 features a full set of protection and diagnostic functions. This includes overcurrent protection (OCP), thermal shutdown (TSD), undervoltage Lockout (UVLO), open-load detection (OL), and detection of plunger movement (DPM). A fault indication pin signals fault events and diagnostic information is stored in the FAULT register.

The MAX22200 is available in a compact 5mm x 5mm, 32-pin TQFN package and operates over the temperature -40ºC to +85ºC range.

The MAX17608 adjustable overvoltage and overcurrent protection device is ideal to protect systems against positive and negative input voltage faults up to +60V and -65V and features integrated low 260mΩ (typ) RON FETs. The adjustable input overvoltage protection range is 5.5V to 60V and the adjustable input undervoltage protection range is 4.5V to 59V. The input overvoltage-lockout (OVLO) and undervoltage-lockout (UVLO) thresholds are set using external resistors. Additionally, the devices offer an internal input undervoltage threshold at 4V (typ). The devices feature programmable current-limit protection up to 1A; hence, controlling the inrush current at startup while charging high capacitances at the output. The current-limit threshold is programed by connecting a resistor from the SETI pin to GND. When the device current reaches the programed threshold, the device prevents further increases in current by modulating the integrated FET resistance. The device can be programed to behave in three different ways under current-limit conditions; Autoretry, Continuous, or Latch-off modes. The voltage appearing on the SETI pin is proportional to the instantaneous current flowing through the device and is read by an ADC. The MAX17608 blocks current flowing in the reverse direction (i.e., from OUT to IN) and features thermal shutdown protection against excessive power dissipation. It is available in a small, 12-pin (3mm x 3mm) TDFN-EP package and operates over the -40°C to +125°C extended temperature range.

For detailed information on the octal solenoid driver, IO-Link transceiver and the reverse and overcurrent protector, refer to the MAX22200, MAX22514 and MAX17608 data sheets.