Battery Formation and Test Solutions

Battery Formation and Test Solutions

A process that can take up to two full days, battery formation and testing involves multiple charges and discharges that activate a battery’s chemistry. This necessary procedure readies the battery for use and is critical to ensure its reliability and quality. Because of how long it takes to complete, this process is a significant bottleneck that prevents battery manufacturing from efficiently and economically achieving greater throughput.

Value and Benefits

Analog Devices addresses battery production challenges by enabling high precision measurement and control to accelerate manufacturing throughput, reduce costs, and ensure the highest quality.

Our application-specific standard products incorporate multi-channel precise voltage and current measurement, and high-resolution bidirectional PWM controller as well as protection functions such as overcurrent protection (OCP), overvoltage protection (OVP), and external overtemperature protection (OTP). Learn more about how advanced battery formation and test systems are enabling electric vehicle manufacturers to scale production.

Enables high-precision measurement and control

Accelerates manufacturing and reduces cost

Enables EV manufacturers to scale production

Featured Products

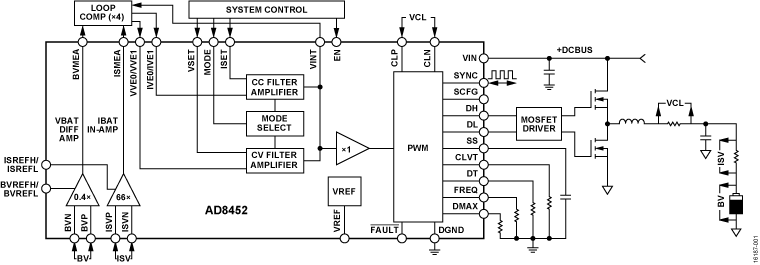

AD8452

Precision Integrated Analog Front End, Controller, and PWM for Battery Test and Formation Systems

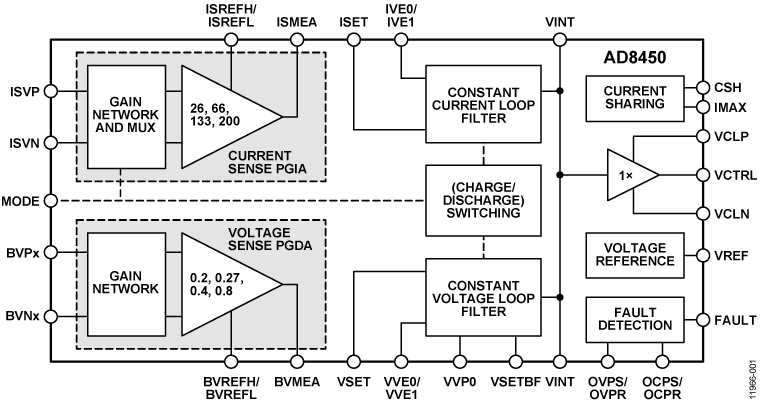

AD8450

Precision Analog Front End and Controller for Battery Test/Formation Systems

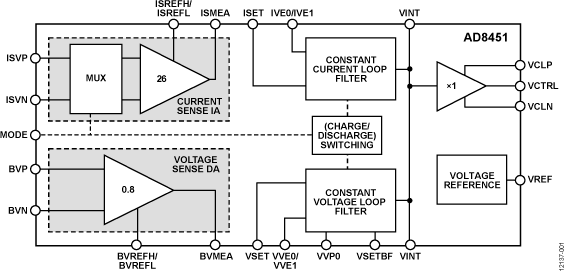

AD8451

Low Cost Precision Analog Front End and Controller for Battery Test/Formation Systems

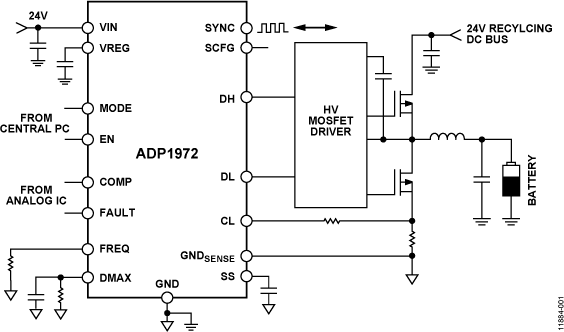

ADP1972

Buck or Boost, PWM Controller for Battery Test Solutions

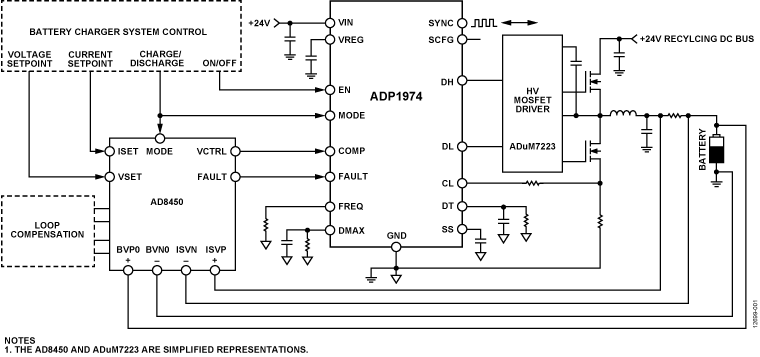

ADP1974

Bidirectional Synchronous PWM Controller for Battery Test and Formation

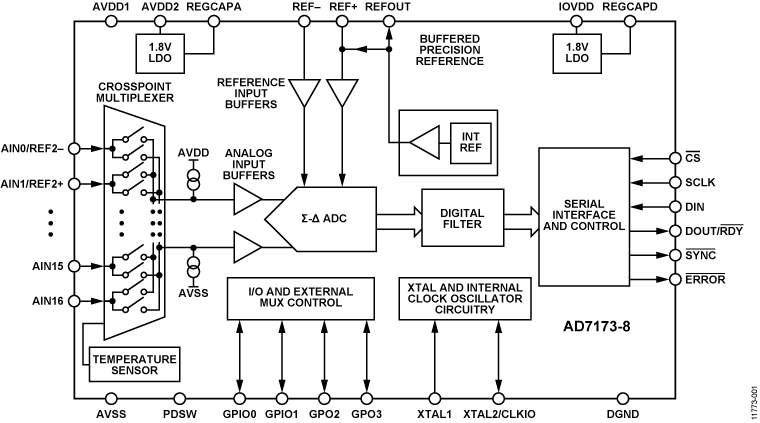

AD7173-8

Low Power, 8-/16-Channel, 31.25 kSPS, 24-Bit, Highly Integrated Sigma-Delta ADC

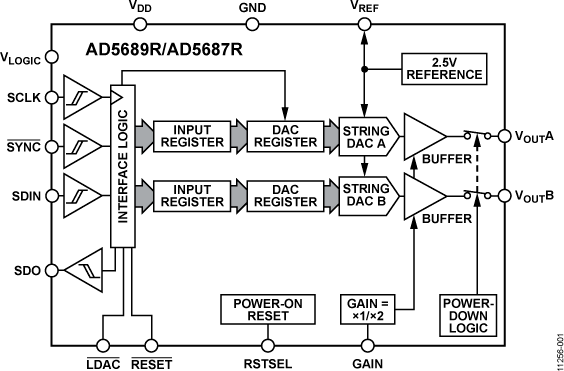

AD5689R

Dual, 16-Bit nanoDAC+ with 2 ppm/°C Reference, SPI Interface

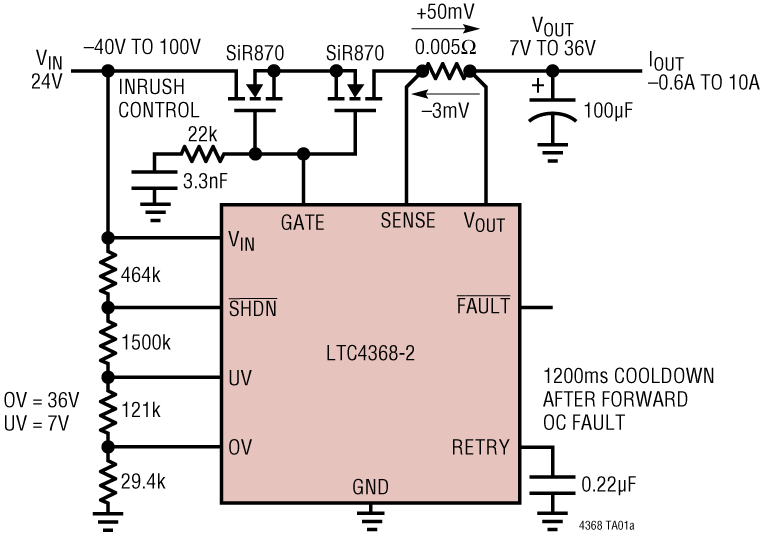

LTC4368

100V UV/OV and Reverse Protection Controller with Bidirectional Circuit Breaker

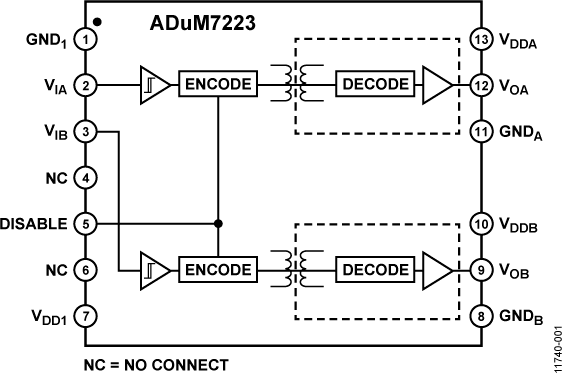

ADUM7223

Isolated Precision Half-Bridge Driver, 4 A Output

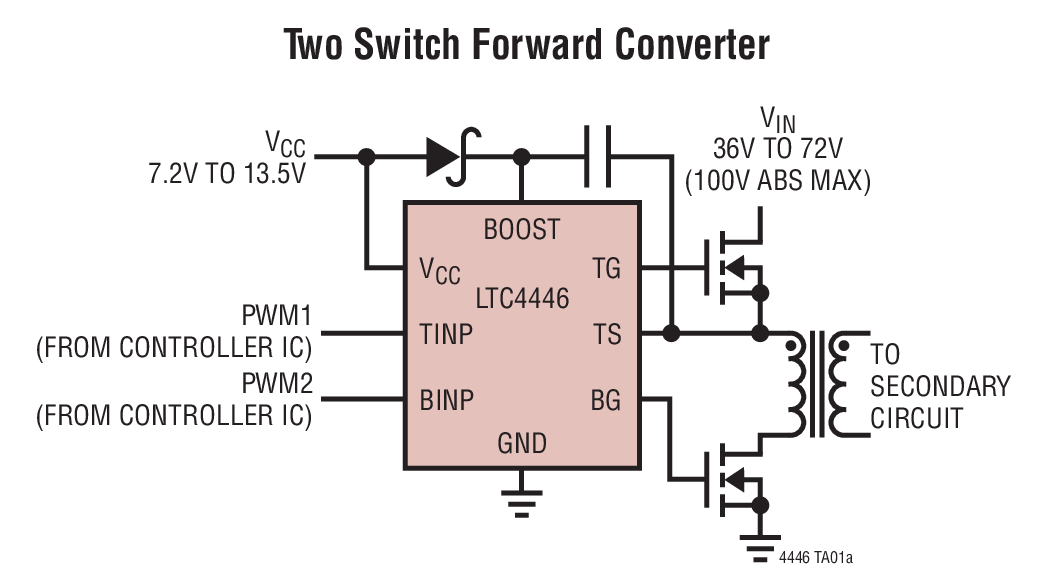

LTC4446

High Voltage High Side/Low Side N-Channel MOSFET Driver

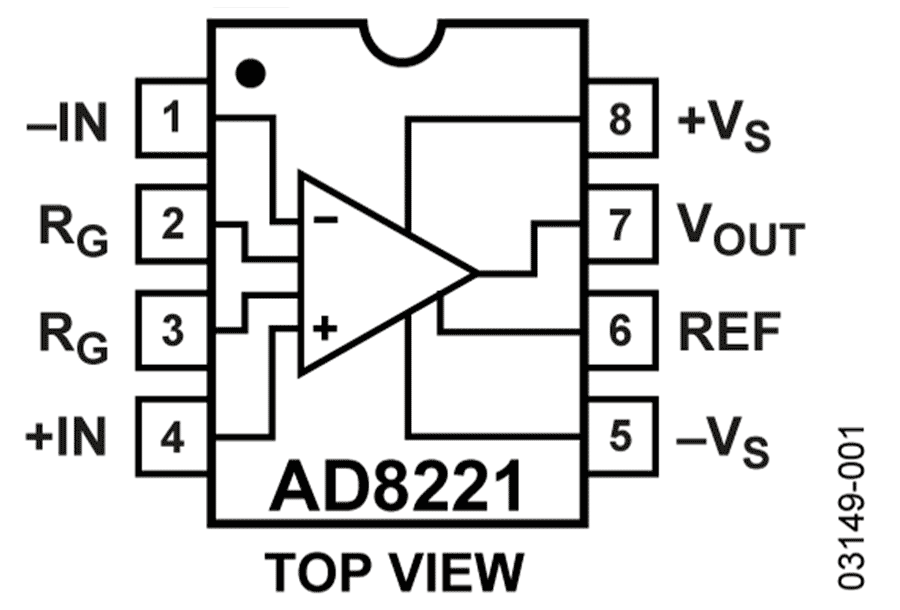

AD8221

Precision Instrumentation Amplifier

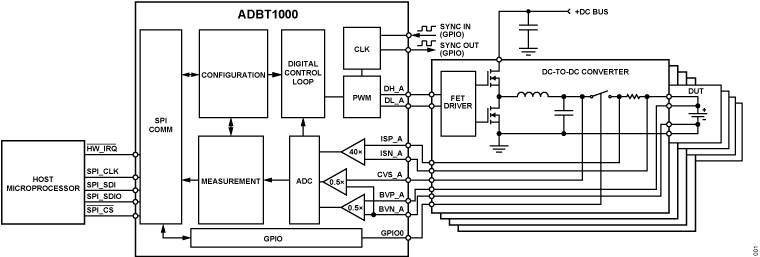

ADBT1000

4-Channel AFE, Digital Controller, and PWM for Battery Formation and Testing

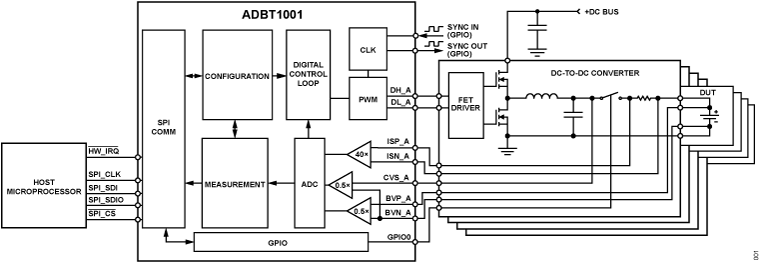

ADBT1001

4-Channel AFE, Digital Controller, and PWM for Battery Formation and Testing

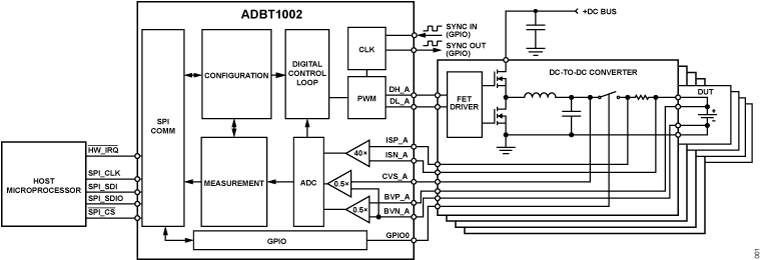

ADBT1002

4-Channel AFE, Digital Controller, and PWM for Battery Formation and Testing

Evaluation Boards

{{modalTitle}}

{{modalDescription}}

{{dropdownTitle}}

- {{defaultSelectedText}} {{#each projectNames}}

- {{name}} {{/each}} {{#if newProjectText}}

-

{{newProjectText}}

{{/if}}

{{newProjectTitle}}

{{projectNameErrorText}}