SIGNALS+ NEWSLETTER SUBSCRIPTION

Stay updated and leverage Signals+ latest insights, information and ideas on Connectivity, Digital Health, Electrification, and Smart Industry.

Thank you for subscribing to ADI Signals+. A confirmation email has been sent to your inbox.

You'll soon receive timely updates on all the breakthrough technologies impacting human lives across the globe. Enjoy!

CloseHYUNDAI’S NOISE CANCELLATION TECHNOLOGY DELIVERS AN IMMERSIVE IN-CABIN EXPERIENCE

Next time you’re traveling in your car, turn off your radio and listen. If you’re in a popular consumer model, you may experience a noticeable level of in-cabin noise. Whether it’s from the engine, tires, or wind, these irritating sounds can cause driver fatigue over long distances and impact safety.

In the past, most auto manufacturers used passive acoustic dampening material to help deaden sound. But that added vehicle weight increased fuel consumption. So, the active noise cancellation technology (ANC) employed in high end audio noise-cancelling headphones was adopted and deployed in millions of vehicles. While ANC is effective for cancelling out a vehicle’s narrow-band engine noise, it wields little influence suppressing the wideband noise generated by the tires (road noise).

At a joint technology workshop with industry leaders Analog Devices, Inc. (ADI) and Hyundai Motors (HKMC), a discussion ensued about road noise cancellation. ADI is a full solutions technology company known for solving the toughest engineering challenges. Hyundai Motors, a pioneer in the automobile industry, wished to distinguish its brand and develop a technology that would dramatically reduce noise in its vehicles.

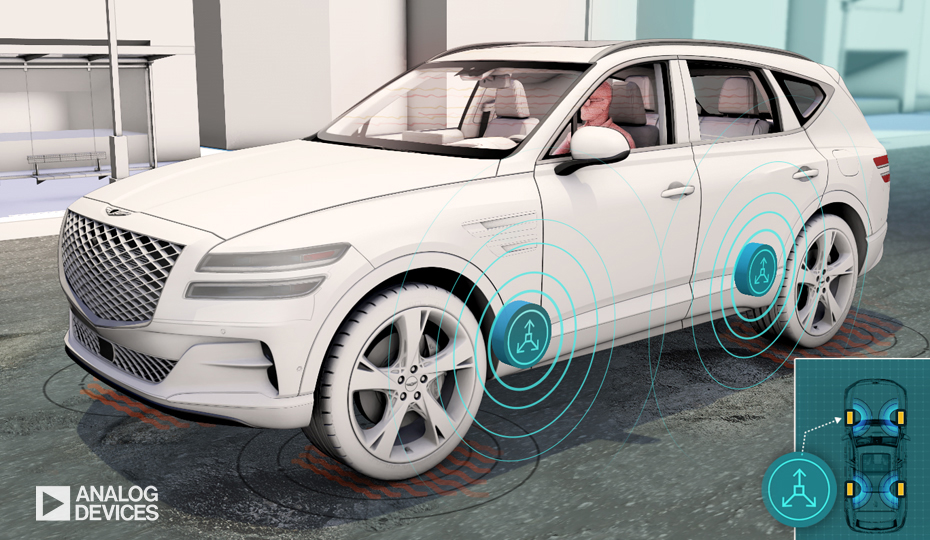

The two teams collaborated to deploy the industry’s first all-digital road noise active noise control (RANC) system. The challenge was to implement RANC in a practical and easily manufacturable way. In early 2020, the groundbreaking RANC system was accelerated to mass production and incorporated in Hyundai’s flagship GV80 cars.

And that’s only the beginning. Hyundai has a vision for building a road to the future—moving far beyond noise cancellation technology to a more immersive, entertaining, high quality sound experience for both drivers and passengers across its entire automotive fleet.

AT A GLANCE

COMPANY

Hyundai Motor Company’s focus is to deliver human-centric, eco-friendly technologies and services that set the foundation to make vehicle operation more convenient, comfortable, and safe.

APPLICATION

Leverage ADI’s Automotive Audio Bus (A2B®) technology for its fundamental audio connectivity and infotainment application capability.

CHALLENGE

Bring to market the industry’s first all-digital road noise cancellation system and make it affordable, less complex, and lighter, and accelerate its deployment to mass production.

GOAL

Develop audio connectivity and infotainment applications across the entire automotive fleet. Develop a more dynamic automotive experience.

TURNING DOWN THE NOISE

In the past, automakers wishing to reduce cabin noise and make their vehicles feel more upscale added sound-deadening barriers—in the floor, cowls—everywhere they could. Even with the advent of lightweight materials, they could only add so much dampening before the additional weight impacted fuel efficiency. So, they turned to a simple analog technology—active noise cancellation—first used in the 1950s to reduce the deafening engine sound inside the cabin of helicopters and airplanes and later popularized by the headphone industry.

ANC is a simple yet elegant solution for cancelling out narrow-band noise rather than just muffling it. Like a ripple in a lake that combines with a trough, ANC acts to flatten out or cancel a sound wave.

The elimination of road noise is not so much about quietness, but the elimination of fatigue that noise generates on the driver and passengers.

*U.S. Department of Transportation, 2021

HOW ACTIVE NOISE CANCELLATION WORKS

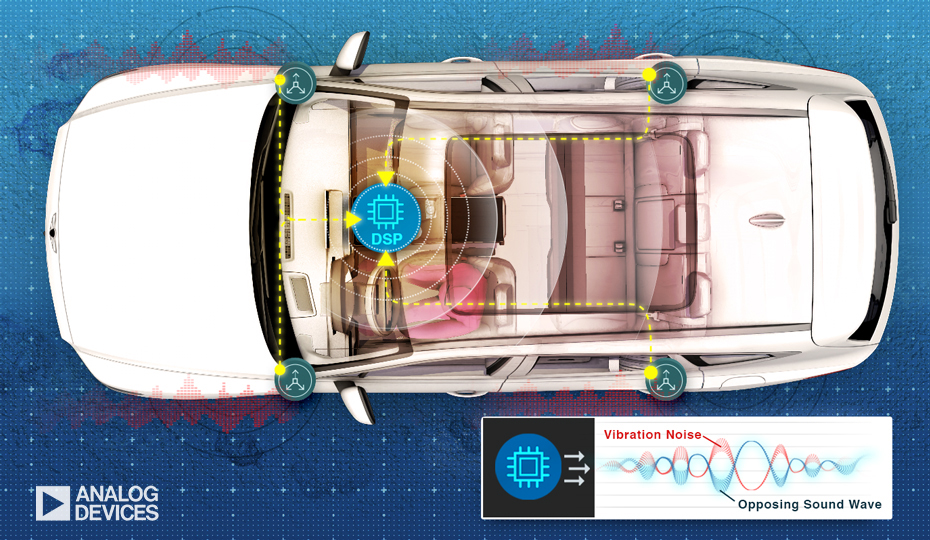

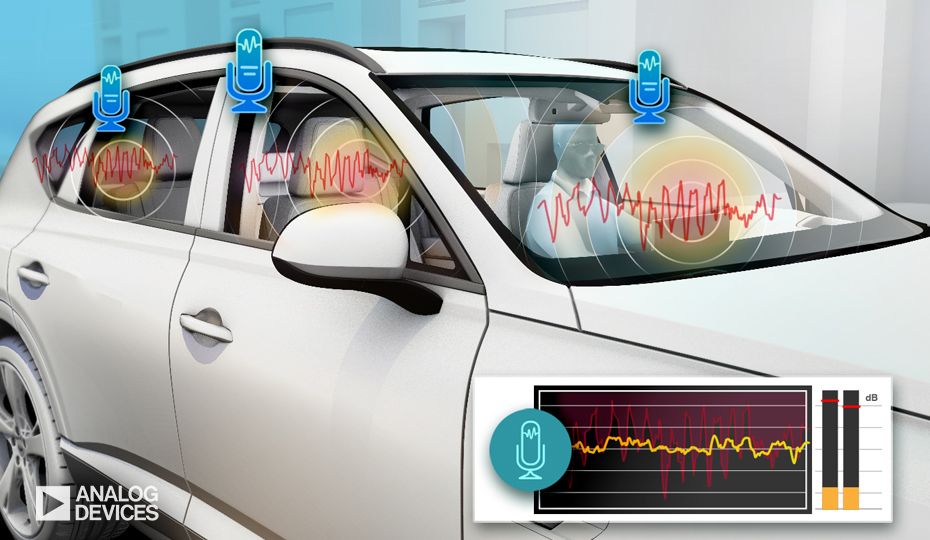

ANC technology works on the same principle as noise-cancelling headphones, employing software and components like DSP and microphones to measure and reduce noise. Mics in the vehicle’s cabin pick up engine noise and relay it to the digital signal processor (DSP) where the ANC algorithm processes it and sends an inverse audio signal back through the speakers. Known as destructive interference, the sound generated is imperceptible to the driver and passengers, but it’s sufficient to cancel out the engine noise.

ANC’S LIMITS

ANC technology is only effective when the noise is constant, predictable, and of low frequency—like the narrow-band rumble of an engine.* Random wideband noise occurrences like potholes bleed through as ANC’s signal and calculation speed can’t react quickly enough to generate a counter wave. Its software and hardware struggle to get the cancellation processed in the 4 ms (4 milliseconds) it takes for road noise to reach the passenger’s ears. Hyundai was in search of a better solution for its vehicles.

*That disadvantage, at times, can act as an advantage. While driving, it’s essential to hear critical sounds—the honk of a car or the siren from a fire truck or ambulance. Since ANC only cancels out low, continuous sounds, these critical higher pitched, irregular audible cues come through loud and clear.

THE ENGAGEMENT

Hyundai and Analog Devices, Inc. (ADI) have a longstanding relationship dating back over a decade. Starting in 2012, ADI provided Hyundai with digital signal processing (DSP) technology for their premium audio amplifiers. Over the next few years, the relationship quickly evolved to focus on Hyundai’s road noise active noise control (RANC).

RANC’s signal latency and processing are not only fast but over four times quicker than the speed of noise traveling from the road to the cabin. In a mere 2 ms (2 milliseconds), RANC analyzes the road noise and sends an inverted sound wave via the car’s stereo speakers, flatlining the noise before anyone in the cabin hears it. In tests, RANC reduced cabin noise by half or 3 dB (three decibels).

Hyundai’s proposed RANC system consisted of four major components:

Early in 2015, Dr. Kang-Duck Ih, a Research Fellow at Hyundai NVH Research Lab, and his team were conducting R&D on algorithms for its RANC applications. ADI engaged with Dr. Ih and team members to introduce a new family of Griffin DSPs (digital signal processors) to implement the RANC algorithm. While discussing RANC architecture, ADI learned that Hyundai’s solution, based on traditional analog connectivity, was prohibitively expensive and could not be deployed. Deployment of automotive road noise cancellation systems across the industry has been constrained by the availability of a cost-effective, low latency networking technology that efficiently connects required input sensors to the DSP.

THE A2B SOLUTION

A2B was presented as a low latency, cost-effective unshielded twisted pair connectivity solution to replace expensive and weight-consuming point-to-point coax cables. In addition to up to 32-channel audio, control, and phantom power over the same cable, A2B was also enabled to optimize the daisy-chain network topology, further reducing wire harness weight and complexity.

Vlad Bulavsky, General Manager of Automotive Cabin Connectivity, Analog Devices Inc. said, “We initially engaged with the Hyundai team to present ADI DSP and A2B technologies and roadmaps. Hyundai’s challenge was a practical implementation of its RANC system. As a result of multiple brainstorming meetings, we were able to come up with a practical and deployable RANC solution using ADI A2B, accelerometers, and Griffin DSP to replace a competitor’s processor for the next generation of Hyundai vehicles.”

Hyundai and ADI met continuously from 2015 to 2016 to collaborate on the solution. The two teams succeeded by deploying the industry’s first all-digital road noise cancellation technology in Hyundai’s GV80, in early 2020.

A2B ADVANTAGE: GREENER CARS. SUPERIOR FEATURES. BETTER DESIGNS.

A2B connects multiple remote sensors for different applications in a daisy-chain sequence, significantly reducing redundant cabling runs. As a result, the cable harness weight is decreased dramatically, while overall design costs and complexity (design, installation, and maintenance) are reduced as a result of fewer cables.

“We have collaborated closely with Hyundai to architect its all-digital RANC system that leverages our A2B technology to reduce equipment cost, weight, and design complexity, and, in turn, improve overall fuel efficiency—helping solve several challenges of the electronic RANC system,” said Andy McLean, VP Automotive Cabin Experience, Analog Devices. “ADI’s work with Hyundai demonstrates A2B’s increasing viability and further distinguishes Hyundai’s vehicles in today’s marketplace.”

“RANC is a great example of an application where different technologies are needed to form an efficient system solution,” said Vlad Bulavsky, “ADI’s DSP, A2B connectivity, accelerometers, and software IP all combine seamlessly to deliver a high performance, cost-effective solution to a very challenging acoustics problem.”

The future holds great promise for RANC and ADI DSP, A2B, and accelerometer technologies applied to electric vehicles (EVs). Engine noise is absent in electric propulsion systems; thus, road noise is more noticeable. Robust noise cancellation technology becomes even more essential in EVs to ensure a quiet cabin and level of comfort.

WITH EYES ON TOMORROW

Better Sound Systems: A car is more than a way to get from point A to B. It’s a reflection of personal lifestyle. Consumers spend more time listening to music in their car than anywhere else. Capitalizing on the advantage of its new quiet cabin, Hyundai has developed stage quality sound, expertly tuned for the road, with its Lexicon® premium audio system with Quantum Logic® Surround. Combining 1050 watts of amplified power with 21 strategically placed speakers and subwoofers in 17 locations throughout the cabin, the GV80 creates an immersive listening experience perfectly tuned for every passenger. While commutes to work in the future may still be arduously long, drivers and passengers can relax in a safer, quieter, and more entertaining personalized space as a result of the ADI-Hyundai collaboration.

RANC AND TIME TO MARKET

For more than 20 years, successful RANC development and implementation by audio manufacturers has been in the news but never mass produced.

How did Hyundai Motors and ADI develop a solution to get to market with scalable production? A key driver of the success of this program is the speed and urgency at which Hyundai Motors and ADI developed the RANC technology. Deep collaboration helped to build synergies that covered vehicle layout, assembly, production, and A/S to get to market fast.