Abstract

Water. It is the most precious managed resource on the planet. Getting clean water to everyone can, in fact, be a matter of life and death. Managing water resources is a serious challenge today. Water is expensive to clean and difficult to get to where it is needed. In fact, connecting people to clean water is one of the great challenges of the 21st century.

With so much at stake, the Internet of Things (IoT) and smart utility grids have an opportunity to improve the world by deploying accurate, reliable water flow-measurement technology. Utilities need to understand and monitor how water is consumed so they can estimate water requirements, but their water meters today do not do a good job of helping us find waste. Given the increasingly scarcity of water resources, we all need to know where every drop of clean water is going. In short, we need a network of ubiquitous, smart water meters.

Drip. Drip. Drip. You may not realize it, but that sound is probably coming from somewhere in your house right now.

Water. It is the most precious managed resource on the planet. Getting clean water to everyone can, in fact, be a matter of life and death. Managing water resources is a serious challenge today. Water is expensive to clean and difficult to get to where it is needed. In fact, connecting people to clean water is one of the great challenges of the 21st century.

With so much at stake, the Internet of Things (IoT)1 and smart utility grids have an opportunity to improve the world by deploying accurate, reliable water flow-measurement technology. Utilities need to understand and monitor how water is consumed2 so they can estimate water requirements, but their water meters today do not do a good job of helping us find waste. Given the increasing scarcity of water resources, we all need to know where every drop of clean water is going. In short, we need a network of ubiquitous, smart water meters.

To date smart water metering technology has focused on communication networks–getting usage data to utilities, Meanwhile, the accuracy of those water meters has been highly suspect. In fact, reliable solid-state water flow-measurement technology has not been able to cross from niche, super-high-accuracy markets to mainstream...until very recently. Consequently, water metering today is an inaccurate, expensive affair, nowhere near ready for the emerging IoT to provide any benefit to water management and nowhere near ready for mankind to start really understanding where our clean water is going. Fortunately, that is ready to change. There is new technology for a solid-state water flow meter that is more accurate and more reliable than traditional mechanical meters. This new ultrasonic, solid-state design is ready for the age of the IoT.

The Long-Standing State of Water Metering

Do not ignore the water drip that you heard a few minutes ago. Think instead of the foundation damage and mold that are probably invading your home right now. Your water meter, meanwhile, is definitely ignoring that drip.

Current water-meter standards have not changed for decades3 and allow for a substantial amount of waste in the system. Water meters are not required to measure below a loss rate of 360 gallons per day, because this is a practical limitation of today's mechanical meters. It is also difficult to guarantee the accuracy of those meters over any period of time. Imagine for a moment how much water 360 gallons per day really is. With your "leak," you could fill a 20,000 gallon swimming pool in less than two months. You could provide drinking water for 400 to 700 adult males per day. You could flush a toilet 60 times per day, or you could support four 10-minute showers a day.

Is this fear mongering? Are we just looking at the governmental agency specifications and creating fear, uncertainty, and doubt? No. Clean water waste through leakage is real. In the U.S., over 1 trillion gallons of water is lost in homes due to leaks per year; 10% of all houses leak at least 90 gallons of water per day.4 Estimates based on careful research show that "in the developing world, nearly half of the water in the system is lost to leaks, theft and overall poor management, or subject to contamination."5 Worldwide, a significant percentage of all clean water is lost before reaching its intended destination.

What an ongoing tragedy. How can we even think about more efficient ways to deliver clean water if we do not know where so much of it is going? How can we make intelligent decisions about water when we cannot accurately determine if a building is leaking a swimming pool's volume of water? Why are we in this situation?

Measuring Water with a Mechanical Meter

There is no conspiracy. Measuring water flow is actually hard. The most obvious way of measuring water flow is just how it has been done for decades–with a mechanical meter. A turbine inside a water meter rotates in proportion to the amount of water that passes, thereby detecting the flow of water. While this approach enables utilities to bill individual customers for their approximate usage, this method has flaws. Consequently, the inaccuracy of a mechanical meter limits our ability to accurately determine where wasted water is going. It also limits the ability for water management to join the modern age, including the IoT.

The traditional mechanical water meters in wide use today suffer from two critical flaws. The first is pure physics. A minimum liquid flow is required to turn the rotor on the meter. The rotor has some fundamental resistance that must be overcome to ensure that it turns in the presence of a flow. This is the driving force behind today's water meter flow-measurement standards that effectively limit the bottom end of accuracy to ¼ gallon per minute (i.e., 360 gallons per day).

The second critical flaw for mechanical metering is contamination. Imagine the filter on your kitchen faucet or the bathtub spigot. Since it was installed new, have you ever seen it truly clean? Chances are that it has some unsightly mineral buildup. Now imagine the problem for water meters with mechanical rotors. Water meters are generally tested for accuracy to 1% across the range of flow expected. This mineral buildup and other corrosive elements in the water will, however, quickly inhibit the accuracy of any mechanical meter.6 In fact, recent studies of mechanical meters found that as much as 89% of various style meters were inaccurate.7 Mechanical meters go out of calibration in as little as two years. When they go bad, they typically go "slow," meaning that the utility is not measuring accurately where the water is going. Over time, water utilities accept a certain amount of loss that is not billed. To stay profitable–that bottom line that we spoke of earlier–they must spread the cost of that wasted, lost water across all consumers.

Improving Measurement Accuracy with a Solid-State Meter

So if mechanical meters have such flaws, what alternative solutions exist? Clearly a solid-state solution would assist with the contamination issue. There are two typical solid-state solutions used in water flow metering today.

The first solid-state solution is magnetic. Fundamentally, a magnetic field is generated and detected through a conductive liquid; the field is proportional to the flow of the liquid. In practice, magnetic flow meters can be highly accurate, but require highly accurate ADCs to achieve measurement resolution at the sacrifice of higher power and generally higher cost. While this kind of resolution (and power and BOM cost) may be practical for distribution water meters or reference water meters, it is not practical for residential water meter or ubiquitous flow meters.

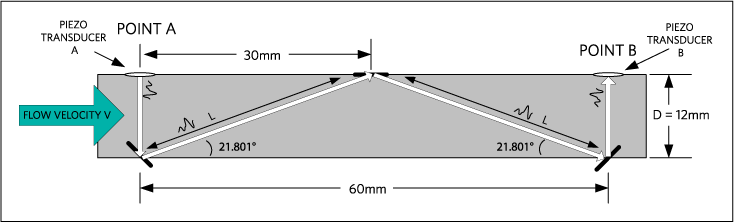

The second solid-state solution uses ultrasonic pulses to measure the flow of water. The general principle here is that two piezo elements in a water pipe will send and receive ultrasonic pulses though the water. The water flowing through the meter will enhance, or impede, the speed of the ultrasonic pulse. Sensors on either side of the pulse will then read and analyze the pulse to determine the phase delta of the analog signal received on the piezo transducer and, from that, calculate the flow rate of the water. Conventional techniques to manage this kind of pulse measurement are expensive and power hungry because today high-precision, high-speed ADCs and DSP processors receive the ultrasonic pulse signals, correlate, and determine the amount of water flow. The cost and power consumption again make this an unacceptable mechanism for measuring water flow.

Given this situation, is it any wonder why residential water metering is still nearly all mechanical? And further, it is no wonder at all why we do not see pervasive flow measurement. We will not, moreover, see flow metering on appliances like hot-water heaters, sprinkler systems, showers, natural gas, propane tanks, and other consumer devices until flow measurement can become lower power and lower cost.

Bringing Accurate, Affordable Water Measurement to the Masses

With solid-state water meters so power hungry and expensive, it is not surprising that the measurement of water flow is stuck in the 20th century, and incapable of joining the IoT. We most assuredly need a cost-effective, power-efficient, solid-state technology that can accurately measure the flow of liquid.

Now we need to talk about time-to-digital converters (TDCs). A TDC is a circuit that receives a start and stop signal and accurately reports a time delta. Sounds simple enough, but what if I told you that it accurately measures a time difference in picoseconds without requiring a THz (1,000GHz) clock? That it only consumes microamps of current?

A TDC-based ultrasonic flow meter (Figure 1) still uses piezo elements to send signals upstream and downstream and measure the time difference (which is where the TDC circuit comes in). However, the "start" and "stop" signals need significant conditioning for us to achieve accurate measurement, such as drivers for the piezos, amplification on the received signal, and temperature compensation. Furthermore, system accuracy can be significantly improved by adding custom control logic to perform several functions: launch and measure multiple pulses, reliably trigger on the first piezo signal, log historical data, handle calibration data, and store multiple entries before waking the system microcontroller (Figure 2).

Figure 1. The spool body in the flow meter is the pipe that the fluid flows through. For ultrasonic flow, the spool body contains piezoelectric elements and mirrors which generate, absorb, and reflect the ultrasonic waves.

Figure 2. A block diagram of the highly integrated MAX35101 flow meter SoC. Note the integrated TDC measurement circuit and analog signal conditioning in the analog front-end (AFE).

The MAX35101 flow metering system-on-chip (SoC) solves the power and the cost problems of solid-state flow meters, and it will help make highly accurate flow metering become ubiquitous. It integrates a TDC measurement circuit, analog signal conditioning, and the micro-DSP and logic needed to provide extremely accurate metering. It solves all of the problems that have thus far prevented water meters from tracking wasted water or joining the 21st century in a connected IoT.

What are the tangible benefits of this technology? There are many.

- Improved accuracy.Today's metering standards ask for accuracy at a low flow rate of ¼ gallon per minute. The MAX35101 can achieve 1% accuracy at 1/16 gallon per minute, which is the currently proposed new measurement level,8 and it can detect leakage at much lower rates. (You do not need 1% accuracy to tell you that there is a leak.)

- Improved longevity. With no moving parts, an ultrasonic solid-state flow meter is less susceptible to corrosion or residue buildup that causes mechanical meters to quickly fall out of calibration. These meters can remain deployed in the field for much longer while maintaining accuracy.

- Improved cost of ownership. With mechanical meters, your accuracy is going to erode or you are going to need to replace the meter every few years. A solid-state meter will last much longer. Utilities will see their operational costs drop from far fewer truck rolls for maintenance and meter replacements.

- Improved BOM cost. Ultrasonic flow meter SoCs need little else to execute accurate energy measurement. This is a striking contrast to other solid-state metering technologies that need DSP processors and high-precision ADCs.

- Lower power consumption. The flow meter SoC will not drive up battery cost because it adds just a few microamps of power consumption to a flow-measurement system. Utilities will also be able to reduce battery size–another cost savings.

Moving Beyond Conventional Water Metering

I would like to know how much hot water I use in a shower, or in the dishwasher, or the clothes washer. I want to detect leaks or excess flow in my sprinkler system. Just the other day I replaced a sprinkler head that popped off a pipe. How long had water flowed from that pipe every morning (wasting water and killing plants) before I saw it and repaired it?

The MAX35101 flow meter SoC is ready for these challenges. It has the low power and longevity so it can be deployed cheaply. It is small and integrated for unobtrusive form factors, accurate enough to detect the emerging low-flow leakage requirements. Water flow can now join the IoT.

Can we realistically envision ubiquitous flow meters in the near future? I know it. Welcome to the 21st century.

Related to this Article

Products

{{modalTitle}}

{{modalDescription}}

{{dropdownTitle}}

- {{defaultSelectedText}} {{#each projectNames}}

- {{name}} {{/each}} {{#if newProjectText}}

-

{{newProjectText}}

{{/if}}

{{newProjectTitle}}

{{projectNameErrorText}}