High-Efficiency Boost Converter Extends Wearable Medical Patch Battery Life

Abstract

Wearable medical devices are transforming the healthcare industry by continuously recording and transmitting the patient state of health. They must be unobstructive and last several days relying on small, disposable batteries. This design solution reviews the shortcomings of a typical power management solution for wearable medical patches and introduces a new, high-efficiency, low-quiescent boost converter that meets the specified operating life.

Introduction

The Internet of Things (IoT) is placing the patient at the center of the healthcare system, with real-time monitoring of vital signs that enables better fitness, disease prevention, and just-in-time medical intervention. Wearable devices incorporate sensors to monitor heart rate, respiration, temperature, steps taken, sleep cycle, stress levels, and whether the user has fallen or otherwise become incapacitated. These devices transmit vital signs over a Bluetooth® Low Energy wireless link to a base station and from there to the cloud, where patients and doctors can access real-time data. This design solution reviews the challenge of powering a wearable medical patch placed on the patient’s chest (Figure 1) and its ability to operate for 5 days on a single disposable zinc-air battery. The battery voltage, regulated by a typical boost converter, fails to meet the device operating time requirement. When powered by a high-efficiency, low-quiescent boost converter, the same device meets and exceeds the five-day operation requirement.

Figure 1. Patient wearing a medical patch.

Typical Wearable Medical Patch System

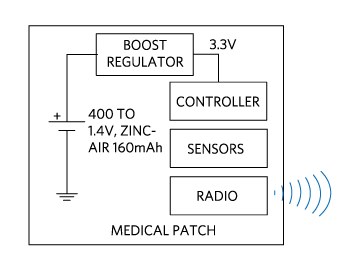

Figure 2 shows a typical medical patch block diagram. A disposable zinc-air battery supplies a charge of up to 160mAh to power the on-board controller, sensors, and radio through a DC-DC step-up regulator.

Figure 2. Typical medical wearable patch block diagram.

In one example, the various sensors collect data for 4 seconds, which are then transmitted by the radio to a centralized receiver with 100ms bursts. In detection mode, the boost converter is loaded with a current of 50µA, while in transmission mode, it provides 48mA to support the radio current pulse. The boost converter load profile is shown below in Figure 3.

Figure 3. Wearable medical patch current profile.

In one typical medical wearable patch application, the system must last for 5 days using only a single disposable zinc-air battery. A typical boost voltage regulator has a quiescent current of 10µA, 85% peak efficiency, and efficiency and 81% efficiency at low current. Assuming 1.4V input and 3.3V output voltage, we can calculate the average current drawn from the battery as follows:

This average current of 1372µA will cause the battery to fall short of 5 days of operation (160mAh/1.372mA = 117 hours).

The Challenges

Achieving high efficiency and low quiescent current with a small-size PCB is challenging for any voltage regulator. Increasing the frequency of operation of the voltage regulator will reduce the size of passives but increase losses, thereby reducing its efficiency. Having the input operation range of the regulator down to fractions of a volt is critical, as the battery voltage falls continuously during operation.

The proliferation of wearable applications creates a need for multiple customized versions of voltage regulators, especially with respect to input/output voltage and current specifications. Accordingly, a medical wearable patch manufacturer may be forced to maintain a sizeable and costly inventory of different regulators and the passives required to support them.

A State-of-the-Art Solution

As an example, the MAX17224 nanoPower synchronous boost converter offers very high efficiency, a 400mV to 5.5V input range, a 1A peak inductor current limit, and an output voltage that is selectable using a single standard 1% resistor. A novel True Shutdown™ mode yields leakage currents in the nanoampere range, making this a truly nanopower device.

Quiescent Current Advantage

Referring to Figure 4, the input quiescent current (IQINT) for the IC is 0.5nA (enable open after startup) and the output quiescent current (IQOUT) is 300nA.

Figure 4. Boost converter with lower shutdown and quiescent currents.

To calculate the total input quiescent current, the additional input current needed to feed the output current (IQOUT_IN) must be added to IQINT. Since the output power is related to the input power by the efficiency (POUT = PIN x ?), it follows that:

IQOUT_IN = IQOUT x (VOUT/VIN)/η

If VIN = 1.4V, VOUT = 3.3V, and efficiency ? = 88% at low current, we have:

IQOUT_IN = 300nA × (3.3/1.4)/0.88 = 803.5nA

Adding the 803.5nA to the input current of 0.5nA yields a grand total input quiescent current of 804nA (IQINGT). This quiescent current is 12 times lower than the 10µA of a typical step-up voltage regulator, as discussed in the previous case.

Efficiency Advantage

The boost converter IC features low-RDSON, on-board powertrain MOSFET transistors that yield excellent efficiency even when operating at frequencies high enough to warrant a small overall PCB size (Figure 5).

Figure 5. High efficiency of a boost converter with low-on-resistance, on-board powertrain MOSFET transistors.

With the boost converter’s 92.5% efficiency at peak current and 0.8µA quiescent current, the wearable medical patch can meet and exceed the required 5 days of operation (see Table 1).

| 160mAh, VIN = 1.4V, VOUT = 3.3V | |||||

| Boost (η %) | Boost Quiescent Current (µA) | Boost Average Load (mA) | Battery Duration (Hours) | Battery Duration (Days) | |

| MAX17224 | 92.5 | 0.8 | 1.26 | 127 | > 5 |

| Competitor | 85 | 10 | 1.37 | 117 | < 5 |

Enable Transient Protection Mode

The IC includes an option for enable transient protection (ETP) mode. When activated by the presence of a pullup resistor, extra on-chip circuitry powered by the output capacitor assures that EN stays high during short transient disturbances at the input. In this case, the quiescent current calculated above increases by a few tens of nanoamps.

BoM Advantage and Smart VOUT Selection

The MAX17224 eliminates the traditional resistor-divider that is used to set the output voltage value in favor of a single-output selection resistor (RSEL), as shown in Figure 4. The chip uses a proprietary scheme to read the RSEL value that consumes up to 200µA at startup only. A single standard 1% resistor sets one of the 33 different output voltages, separated by 100mV increments between 1.8V and 5V. The result is a small reduction in BOM (one less resistor), simplified inventory (a single regulator for multiple applications), and lower quiescent current.

Conclusion

The Internet of Things, combined with low-power wireless data transmission protocols, is enabling the continuous and real-time monitoring of patient life signs by means of wearable devices. We reviewed the challenges of powering a wearable medical patch with a small disposable 160mAh zinc-air battery. A typical boost converter that regulates the battery voltage falls short of the five-day operating requirement for wearables. On the other hand, a high-efficiency, low-quiescent boost converter can meet and exceed the requirement of five-day operation.

A similar version of this design solution originally appeared on How2PowerToday on February 14, 2020.

Related to this Article

Products

PRODUCTION

400mV to 5.5V Input, nanoPower Synchronous Boost Converter with True Shutdown

PRODUCTION

400mV to 5.5V Input, nanoPower Synchronous Boost Converter with True Shutdown

PRODUCTION

400mV to 5.5V Input, nanoPower Synchronous Boost Converter with True Shutdown

Product Categories

Resources

{{modalTitle}}

{{modalDescription}}

{{dropdownTitle}}

- {{defaultSelectedText}} {{#each projectNames}}

- {{name}} {{/each}} {{#if newProjectText}}

-

{{newProjectText}}

{{/if}}

{{newProjectTitle}}

{{projectNameErrorText}}