Overview

Design Resources

Evaluation Hardware

Part Numbers with "Z" indicate RoHS Compliance. Boards checked are needed to evaluate this circuit.

- MAXREFDES281# IO-Link Data Link Controller Reference Design with PMOD Connector

Device Drivers

Software such as C code and/or FPGA code, used to communicate with component's digital interface.

Description

Advanced factory automation solutions (i.e., Industry 4.0) require an increasing number of smart sensors and smart actuators, which are typically controlled using IO-Link® point-to-point serial communication between the sensor/actuator and IO-Link master. As a leading provider of IO-Link device transceiver and master transceiver ICs, Analog Devices, Inc., also provides complete reference design solutions to help our customers improve their time to market. These proven designs cover all the hardware and software requirements needed for compliance with the IO-Link standard.

IO-Link is the first open, field bus agnostic, low-cost, point-to-point serial communication protocol used for communicating with sensors and actuators that has been adopted as an international standard (IEC 61131-9). IO-Link standardizes interoperability of industrial equipment from all over the world. IO-Link can function directly from a PLC or be integrated into standard field buses, quickly making it the de-facto standard for universally communicating with smart devices like the MAXREFDES281#.

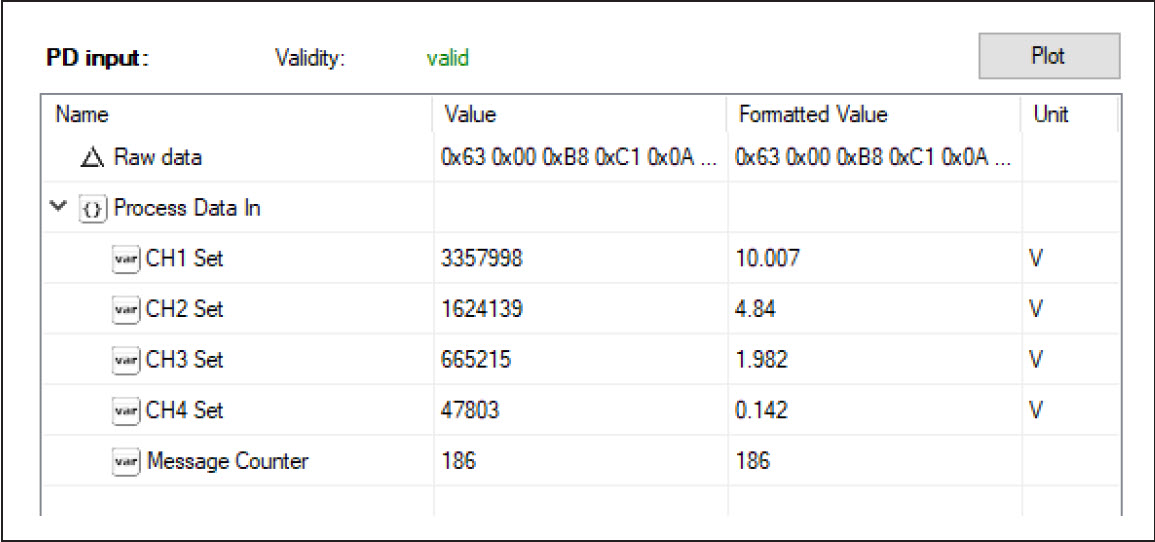

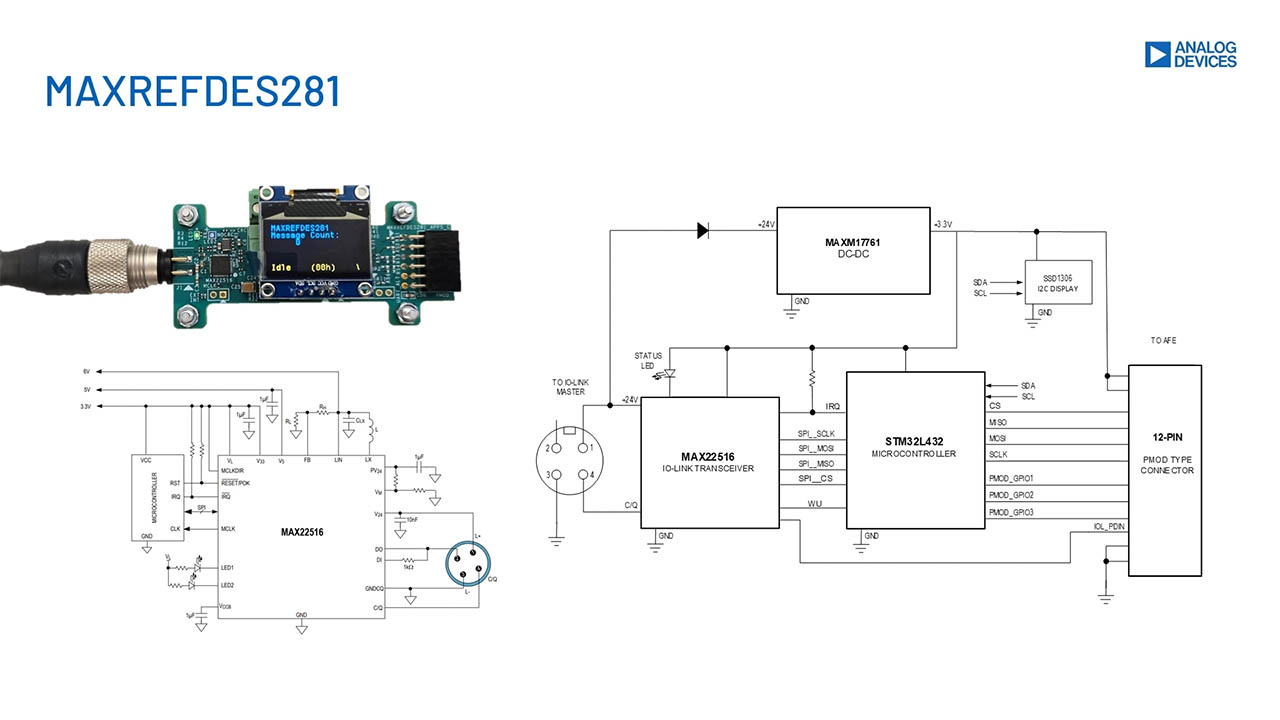

The MAXREFDES281# is a complete, IO-Link reference design that allows an engineer to connect device or actuator development boards with a Pmod™-compatible peripheral module connector, and interface to an IO-Link Master. The MAXREFDES281# consists of a MAX22516 IO-Link transceiver with integrated data link controller and protection, a microcontroller to run application code, and has a peripheral module connector to connect device or actuator functions, supporting SPI, I2C, or UART interfaces.

The complete reference design fits on a 75mm x 33mm printed circuit board (PCB). Design files and software are available on the Design Files folder. The board is also available for purchase.

Features & Benefits

- IEC 61131-9-Compliant

- IO-Link Version 1.1-Compliant

Parts Used

Details Section

Documentation & Resources

-

MAXREFDES281 Design Files8/2/2022ZIP1 M

-

MAXREFDES281: IO-Link to Pmod Adapter (Rev. 0)1/9/2024PDF1 M

-

MAXREFDES281 Programming4/15/2025

MAXREFDES281 Programming4/15/2025 -

MAXREFDES281 Introduction and Demonstration4/4/2025

MAXREFDES281 Introduction and Demonstration4/4/2025

Support & Training

Search our knowledge base for answers to your technical questions. Our dedicated team of Applications Engineers are also available to answer your technical questions.