摘要

The world is becoming a smarter place. We have come to expect more out of devices, communications, and networks. Think smart meter and smart grid. Although “smart” means different things to different people, broadly speaking it simply implies more capability and more features. It suggests the ability to make intelligent decisions. This is why new static meters are beginning to displace traditional mechanical meters for residential water metering.

We are in the early stages of increased intelligence in the services delivered to our homes. Led by the electricity providers' smart meters and the smart grid, real-time monitoring and control of electrical devices are becoming more and more common. This real-time access to information is desirable and beneficial to the service provider as well as the residents whom they serve. With real-time measurement and status monitoring we can understand our usage and the impact(s) of our decisions, and even identify problem conditions. It is only natural that the desire for this intelligence be extended beyond electricity usage to all aspects of service delivered to the modern home.

Coincident with the desire for smarter services is the need for improved accuracy for water metering and, ultimately, reduced waste. It is estimated that more than one trillion gallons of water leak from U.S. homes each year and 10% of homes have leaks that waste 90 gallons or more per day.1 Because of poor accuracy associated with existing meters, these leaks often go undetected.

Flow-Meter Snapshot

Water is the dominant commodity measured by flow meters. IMS Research estimates that the water-meter market will reach about 120 million units annually by 2016.2

Flow meters conjure up thoughts of large, clunky, metallic, industrial-looking devices. This is hardly what we think of as modern, smart technology. Frankly speaking, the technology for the majority of the installed flow-meter base is quite dated. The metrology technology for flow meters is basically one of two varieties, positive displacement or velocity. In positive displacement meters, discrete units of a fixed volume are counted when a piston cylinder, reservoir, or diaphragm is filled and subsequently released in a repeated fashion. In velocity meters, the flow of the liquid is measured and the volume is inferred since the diameter of the pipe is known. While these traditional mechanical meters have served us well over the decades, it is time to move forward to better metering technology and the benefits that it brings.

Limitations and Impact of Mechanical Flow Meters

In spite of their long history, mechanical meters have significant accuracy and reliability limitations. The issue of accuracy is particularly problematic at low flow rates. Because a fine measurement capability is not available at an affordable price, mechanical meters typically undermeasure or simply do not register any flow at low flow rates.

Reliability is also problematic. Mechanical meters tend to slow down over time and with use. Friction and abrasive wear-and-tear degrade their performance. Stated another way, mechanical meters tend to undermeasure flow with progressively worse accuracy over time.

The impact of low-flow accuracy and degrading performance over time is significant. The low-flow performance makes leak detection difficult or impossible. In the U.S. the minimum flow rates at which cold-water meters are required to be tested by the American Water Works Associated (AWWA) have not changed since the first standard was proposed in 1921.3 The minimum flow-rate accuracy requirement is currently at 1/4 gallon (0.95 liters) per minute. A continuous flow at this rate is equivalent to about 1,363 liters/day. This is wasted water. The waste also leads to higher bills for all consumers, because utilities recover the cost of these water losses through higher and more frequent rate increases.

The Natural Resources Defense Council (NRDC) in partnership with utilities across the U.S. has submitted a proposal to reduce this waste. The NRDC proposes that a "Leak Detection Test Flow" be added that requires measurement of flow rates down to 1/16 gallon/minute, or 0.01m3/hr, with accuracy between 80% and 101% of the water that actually passes through the meter.4 To meet this requirement, significant water-meter accuracy improvements are needed.

Emergence of Static Metering

Fortunately, new, improved, "static" metering technologies are on their way to the smart home. A static meter, which is any metrology device with no moving parts, has significant advantages over traditional mechanical meters. Static meters have already been used for years in the commercial and industrial markets.

Static meters have significantly better accuracy, especially at low flow rates. Furthermore, due to their lack of moving parts, they are more reliable and their performance does not degrade over time. With less leakage, there is less waste and loss. Consequently, the service provider is not billing the cost of lost revenue back to the consumer.

Static meters are classified as electromagnetic and ultrasonic time-of-flight. In an electromagnetic meter, a magnetic field is applied to the pipe and a voltage is generated perpendicular to the flux lines. This voltage is proportional to the flow rate. While this type of meter provides excellent accuracy, it tends to have fairly high power consumption.

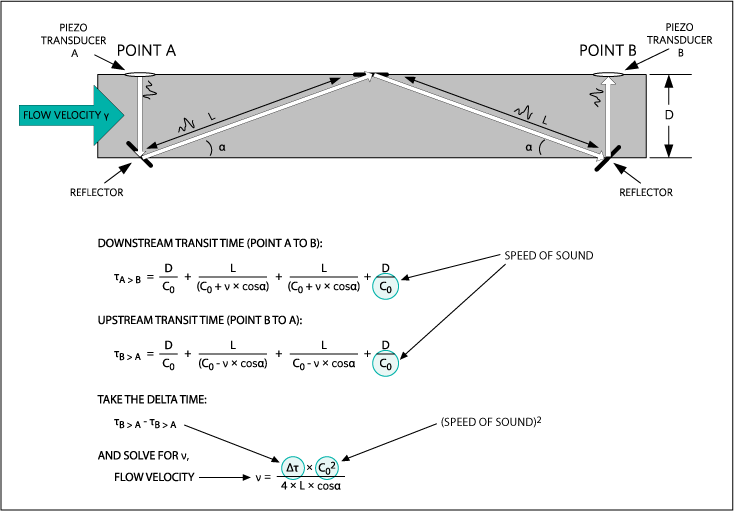

The dominant type of static meter technology today is ultrasonic time-of-flight. In this meter, a piezo transducer is pulsed. The resultant acoustic wave travels through the media (water in our discussion) and is picked up at a second piezo transducer downstream. After this path is completed, the piezo transducer signals are reversed; the downstream piezo is pulsed and the upstream piezo picks up the signal. The difference in the time of flight for the two pulses enables the measurement of the flow, since the acoustic wave's speed is proportional to flow. Figure 1 shows a time-of-flight difference calculation in a typical spool body with ultrasonic transducers.

The delta time-of-flight value corresponding to the previous target of 0.01m3/hr leak-detection test flow is around 1.2ns for pipe sizes less than 3/4in (19.1mm). At 1.2ns, the measured time of flight must be between 960ps (80%) and 1212ps (101%) to meet the required accuracy.

Figure 1. Example time-of-flight difference calculation.

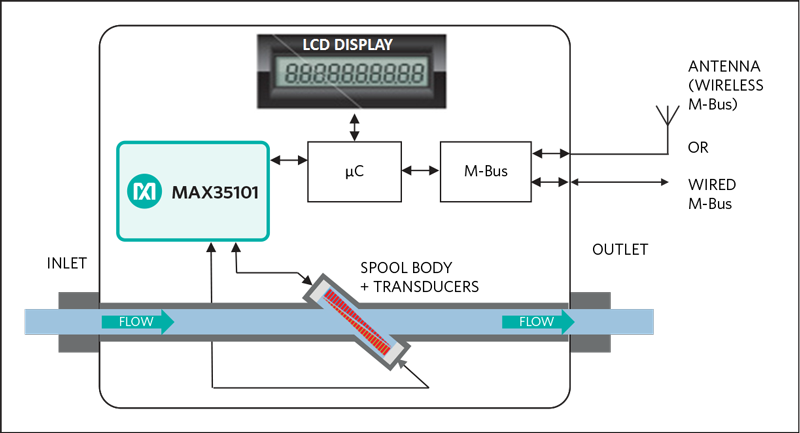

A block diagram of the electronics for an ultrasonic time-of-flight flow meter is shown in Figure 2. Here a dedicated, ultrasonic time-of-flight IC, the MAX35101, interfaces with two piezos. Each piezo alternately functions as an acoustic wave generator and receiver, depending on the direction of the pulse. The IC uses a highly accurate time-of-flight core that has 20ps accuracy, providing excellent flow-rate accuracy. While the ultimate accuracy depends on the pipe diameter and flow rate, this architecture can provide leak detection below 1 liter per hour and remain accurate to EN and OIML specifications for the lifetime of the meter.

Figure 2. Water meter ultrasonic time-of-flight solution features the MAX35101 time-to-digital converter with analog front-end (AFE).

Implementing Static Metering

Until now the technology for static meters was not practical for residential water use. However, recent evolutionary changes in service delivery are creating opportunities.

The greatest challenge for residential use of static meters is straightforward: power. It takes power to operate an electronic device. Because most water meters are not wired for power, static meters traditionally were not a practical option. With the onset of AMR (advanced meter reading) and AMI (advance meter infrastructure), this is changing. AMI and AMR enable remote meter reading and/or control, typically with wireless communications technologies.

When a service provider decides that they need the capabilities of AMI/AMR, they now need to power the meter, either through a line voltage or from a battery. Since power has to be provided to the meter anyway, this opens the door to static metering. The power required for static metering adds to the power requirements to be sure, but it does not create a new challenge. Concurrent improvements in battery technology are helping drive the change in meter technology. Because power densities are improving, the life of the meters is also increasing. It is not uncommon to see static meters with a battery life of 15 or more years.

Other factors are driving the residential adoption of static meters, notably improved leak detection and the ability to act on that information. A meter that can detect a leak and then react, such as through an automatic valve shutoff, adds significant safety to the home. While not necessarily an immediate safety hazard, water leak detection could spare the homeowner unnecessarily high water bills and prevent water damage.

Conclusion

Smart meters. The smart grid. Smart technology. We live in a smarter world where more intelligent decisions are being pushed back to smarter devices. This is certainly true for water meters in residential use. The service delivery infrastructures to our homes are becoming more intelligent. Static residential water metering are emerging technologies destined to replace the traditional mechanical meters that we see everywhere now. While still in infancy, static meters promise to add even greater accuracy and reliability. Costs will decrease with scale as the need for the smart infrastructures increases. There is little doubt that static metering will enable better management of our natural water resources, improve safety, and provide a better consumer experience.

关联至此文章

产品

{{modalTitle}}

{{modalDescription}}

{{dropdownTitle}}

- {{defaultSelectedText}} {{#each projectNames}}

- {{name}} {{/each}} {{#if newProjectText}}

-

{{newProjectText}}

{{/if}}

{{newProjectTitle}}

{{projectNameErrorText}}