概览

设计资源

描述

Industry 4.01 marks the fourth industrial revolution, characterized by distributed, intelligent control systems. Breaking from a past with large, centralized programmable-logic controllers, Industry 4.0 allows for highly configurable, highly modular factories, which accept an ever increasing number of sensor inputs, while operating at a higher output than ever before. The ultra-small PLC, or MicroPLC, lies at the heart of the Industry 4.0 factory, providing high performance with ultra-low power consumption, in an ultra-small package. MAXREFDES63 is Analog’s Micro PLC octal-channel, digital output card.

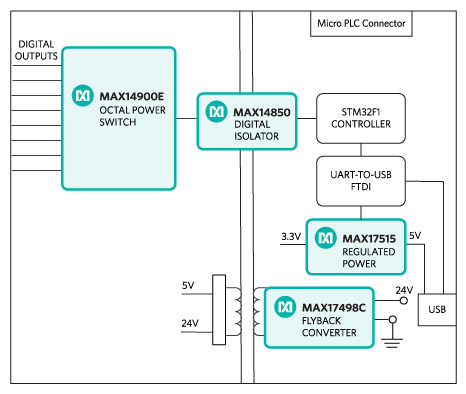

The MAXREFDES63 reference design (Figure 1) features eight-channel digital outputs with isolated power and data. The design integrates a 600VRMS data isolation (MAX14850); a STM32F1 microcontroller; a FTDI USB-UART bridge; a high-efficiency DC-DC converter (MAX17515); and isolated/regulated +22V, and +5V power rails (MAX17498C). The entire system typically operates at less than 400mW and fits into a space roughly the size of a credit card.

Figure 1. The MAXREFDES63# reference design block diagram.

优势和特点

- Isolated power and data

- Micro PLC form factor

- Device drivers

- Example C source code

重要通知及免责声明

请阅读关于ADI设计信息和资源的参考设计免责声明。

详情

文件和资源

-

MAXREFDES63 Design Files2021/2/17ZIP5 M

支持与培训

搜索我们的知识库,获取技术问题答案。我们专门的应用工程师团队也会随时为您解答技术问题。